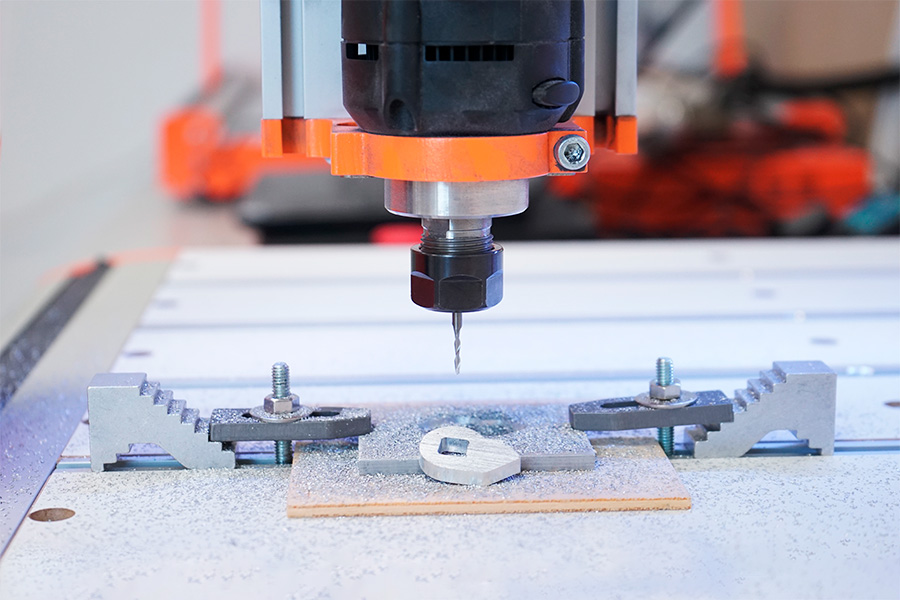

CNC Aluminum

Milling aluminum: Alloys, tips, tricks and end mills

Aluminum is a versatile material used in CNC machining due to its low density, good mechanical properties and excellent corrosion resistance. When milling CNC aluminum on a CNC machine, however, there are some important aspects to consider in order to achieve optimal results. We explain which aluminum alloys are suitable for milling and give you tips for milling aluminum, suitable end mills and the required milling parameters.

Advantages of aluminum

Milled parts made of aluminum are light but highly stable. This makes CNC aluminum a material in demand wherever a high strength-to-weight ratio is required. Thus, aluminum parts are used from the automotive industry to mechanical engineering to aerospace technology. CNC aluminum is also not only easy to machine, but also has high thermal conductivity, natural corrosion resistance and good electrical conductivity.

- High strength-to-weight

- Corrosion resistance

- Easy to machine

- High thermal conductivity

- Good electrical conductivity

Aluminum milling - Tips und Tricks

Milling CNC aluminum requires specific knowledge and techniques to achieve optimal results. With the right tips and tricks, you can improve your milling skills and work more efficiently. From choosing the right end mill for aluminum to adjusting cutting speed and feed rates to optimal cooling and chip removal, there are various aspects to consider. With these tips, you will be able to achieve precise and high-quality results when milling aluminum.

Lubrication and cooling

Aluminum generates high temperatures during milling, so lubricating aluminum and cooling aluminum is very important. Use a suitable cooling lubricant solution to dissipate the heat and facilitate the formation of chips.

Optimized chip removal

Aluminum chips can easily accumulate and impair the milling process. Therefore, use spiral flute end mills or end mills with special chip spaces to ensure effective chip removal.

Pay attention to safety

Always wear safety glasses and hearing protection during aluminum processing. Aluminum chips can fly around when machining aluminum, so it is important to protect yourself properly.

Adjust feed rate

Aluminum typically requires higher feed rates than other metals. Experiment with different feed rates to find the optimum speed for your milling application.

Reduce cutting speed

Aluminum requires lower cutting speeds than wood, for example. Be sure to select the correct cutting speed depending on the diameter of the end mill and the type of aluminum alloy.

Keep tabs on tool wear

A dull end mill can lead to poor surface quality and this in turn to increased heat generation and longer machining times. Replace the end mill in time to achieve optimum results.

Alumninum alloys for milling

Not all aluminum is the same. There are different alloys, some suitable for milling and others not. An alloy is a mixture of at least two metallic elements, at least one of which must be a metal. Combining the metals creates a new substance with altered properties compared to the pure starting materials. Alloys are produced to improve or adjust the properties of metals, such as strength, hardness, corrosion resistance or melting point. When milling CNC aluminum, different alloys are used, depending on the specific requirements and subsequent application. We have listed the best millable aluminum alloys for you.

|

EN-Identification |

No. |

Old Norm |

Machining |

Welding |

Anodizing |

Description |

|

EN AW-2007 |

31.645 |

AlCuMgPb |

very good |

poor |

poor |

Good strength, machinability and moderate corrosion resistance. Use in mechanical engineering, automotive and other mechanical applications. |

|

EN AW-2011 |

31.655 |

AlCuBiPb |

very good |

poor |

poor |

Good machinability and high strength. Use in mechanical engineering, the automotive industry and other applications. |

|

EN AW-2017 |

31.325 |

AlCuMg1 |

very good |

poor |

poor |

High strength, good machinability and good corrosion resistance. Use in mechanical engineering, electronics industry and transport applications. |

|

EN AW-6012 |

30.615 |

AlCuSiPb |

very good |

poor |

poor |

Good combination of strength, corrosion resistance and weldability. Commonly used in the automotive industry, especially for sctructural components, body parts and frames. |

|

EN AW-6026 |

- |

AlCuSiBi |

good |

good |

good |

High strength, good corrosion resistance and good weldability. Use in the automotive industry, especially for structural components and body parts. |

|

EN AW-7075 |

34.365 |

AlZnMgCu1,5 |

very good |

poor |

medium |

High strength and excellent stiffness. Commonly used in applications requiring high load capacity, such as in the aerospace industry. |

Milling Cutters for aluminum

Choosing the right end mill is crucial for effective machining of CNC aluminum. From shank cutters, solid carbide end mills and HSS end mills with special cutting edge geometries to indexable insert end mills for efficient chip removal, there are various milling cutters with which CNC aluminum can be machined. The selection of the appropriate milling cutter also depends on the aluminum alloy you are using. Learn about the different types of milling cutters and their properties. So you can quickly find the right milling cutter for your workpiece.

Shank cutters

Shank cutters have a cylindrical shank and are versatile. Whether you choose a 1-flute, 2-flute 3-flute or 4-flute depends on the aluminum alloy you want to machine. To minimize wear, a basic rule of thumb applies: The harder the CNC aluminum, the more flutes you should use.

In short:

- Milling cutters with cylindrical shank

- 1-, 2-, 3- or 4-flutes possible

- Number of flutes depends on the hardness of the CNC aluminum

HSS End Mill

HSS cutters are milling tools made of high-speed steel. HSS is a special tool steel that has a high hardness and wear resistance. HSS cutters are therefore not only particularly durable, but also versatile and available with different designs and cutting edge geometries.

In short:

- End mills made of high speed steel

- Particularly durable

- Different cutting edge geometries available

Indexable insert milling cutters

Indexable insert milling cutters, such as the Amana face milling cutter, consist of a milling body and replaceable inserts that have different cutting edges. These inserts can be rotated or replaced when they become worn. The indexable insert milling cutter enables precise and efficient milling in a variety of applications.

In short:

- Milling cutter body with replaceable inserts

- Inserts can be rotated and replaced

- Durable and cost efficient

Solid carbide end mill

Solid carbide end mills are designed for high cutting speeds and feeds. They are usually made mainly of tungsten carbide. Due to their hardness and wear resistance, solid carbide cutters have a long tool life and are suitable for demanding milling work.solid carbide cutters are available in various designs and cutting edge geometries.

In short:

- End mill made of solid carbide

- Particularly hard, wear-resistant and heat-resistant

- Different cutting edge geometries