Shapes shift in the X axis

I made my first part with the 600SF and the result is a bit strange.

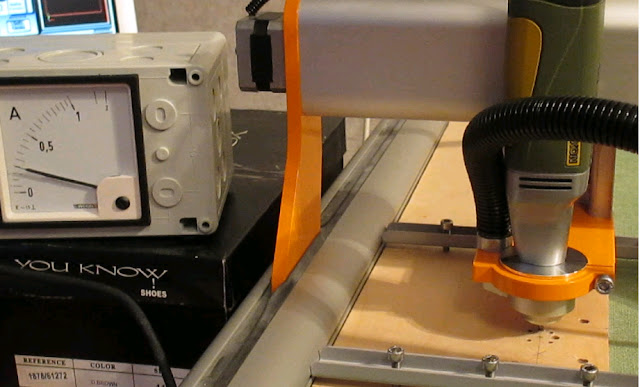

Here are the pictures (the part has the same position in both photos and emergency switch is at the lower right corner):

All the individual shapes seem to shift towards the -X direction (towards right on the picture). If we look at the centre area then the large hole is right of the four medium holes and the medium holes are right of the four small holes. The tolerances of the hole diameters are within 0,05mm for all centre area holes when measured at 0/45/90 deg directions. The large circle that contains all of the centre area holes should be 40mm in diameter, but it is between 39,77/39,81/39,84 when measured at Y/45deg/X directions (tolerance of 0,07mm is very good for me). When I place the circle vertically on a table and give it a little push it rolls quite smoothly and doesn`t bounce like an out of shape object should.

The shortest distance between the outer holes is 40+/-0,02mm (up and down photo direction) as it should be, but the distances from left to right are 38,97mm and 38,78mm. The outer square should be 59x59mm but it is from 58,08 to 58,19mm(again the tolerance is very good).

Order of machining:

Two holes on the right- 4 smallest holes at the centre- 4 medium holes at the centre- large hole in the middle- big circle- two left holes- square.

In conclusion all of the shapes shift to the -X direction (right). The smaller holes have all correct dimensions and tolerances. The larger shapes have smaller dimensions, but the tolerances are within limits (circle and square). If the machine X axis moved less than it should then the shapes should be out of proportion, shouldn`t they? I`m a bit lost here.

Stepcraft 600SF (version 1) parallel port

Proxxon IBS/E

Mach3

devCad Cam Pro; devWing Cam; devFus Cam; Profili Pro 2

I could be back on track now. There is a possibility that I wnted too much from the machine. My first program for making the part consisted of over 500 g-code lines, it had very small radius helical plunge movements into the material and feedrate could have been too large for modelbuilding plywood.

I made a new program for the same part that has about half as much g-codes, simple vertical plunge, conventional milling and reduced feedrates. Rpm is still 20000, but took the same feedrates as the user heustec describes here: https://www.stepcraft-systems.com/en/service-support/stepcraft-forum-uk/operation/909-plunge-and-feed-rates#9377

Used some light supermarket fruitbox plywood this time for testing. The results are very good, will try again with harder grade plywood soon.

Stepcraft 600SF (version 1) parallel port

Proxxon IBS/E

Mach3

devCad Cam Pro; devWing Cam; devFus Cam; Profili Pro 2

Stepcraft 600SF (version 1) parallel port

Proxxon IBS/E

Mach3

devCad Cam Pro; devWing Cam; devFus Cam; Profili Pro 2

The results are heavily dependant on your machine setup and on the speed you machine at. It also depends on the rapid feed rates.

Stepper motor torque drops off as you increase the RPM.

Faster speeds

Higher Motor RPM

Torque drops

if you get to a stage where your drive power and machining power requirements meet the lowered torque due to RPM increase - then you can start to loose steps and loose position.

The stepper systems are open loop - in that the signal is sent from Mach3/UCCNC/WinPC to the drive and then to the motor. The system assumer the motor moves. If the motor stalls a little the software will not realise this and keep going.

bigger servo applications have encoders on their motors to check the position.

Given your "machined parts" are within tolerance - and their individual positions are not - then what most likely happened is that the machine lost some position when moving from one machining operation to another. This is when the machine moves at max speed (rapid moves).

its is likely that after first work - the machine "bedded in" and is now happy to move at max speed.

sometimes the machine can stall during an operation if pushed too hard.

you have to watch

-depth of cut

-feedrate

-spindle speed

-cutters

- and bear in mind that these will change with materials used.

rule of thumb is to start slow and build up. However - tread carefully - cutters spinning fast and yet being fed slowly can cause excess heat to build up. Friction from the process will kill cutters and overhead work zone.

With routers its better to machine shallower cuts, move quicker (within reason) and keep the spindle speed high. Routing spindles have max power at max RPM. It drops off significantly with lower RPMs.

great analysis of your issue here. Very comprehensive. well done.

- 44 Foren

- 7,436 Themen

- 63.4 K Beiträge

- 9 Online

- 26.5 K Mitglieder