Vincent - Stepcraft D600 (2018)

Hello

I live in Belgium, in Brussels.

I am an electromechanical technician

My passions are Python3, C++, Arduino, BMW E30 Hartge H27X Touring renovation, Books, etc...

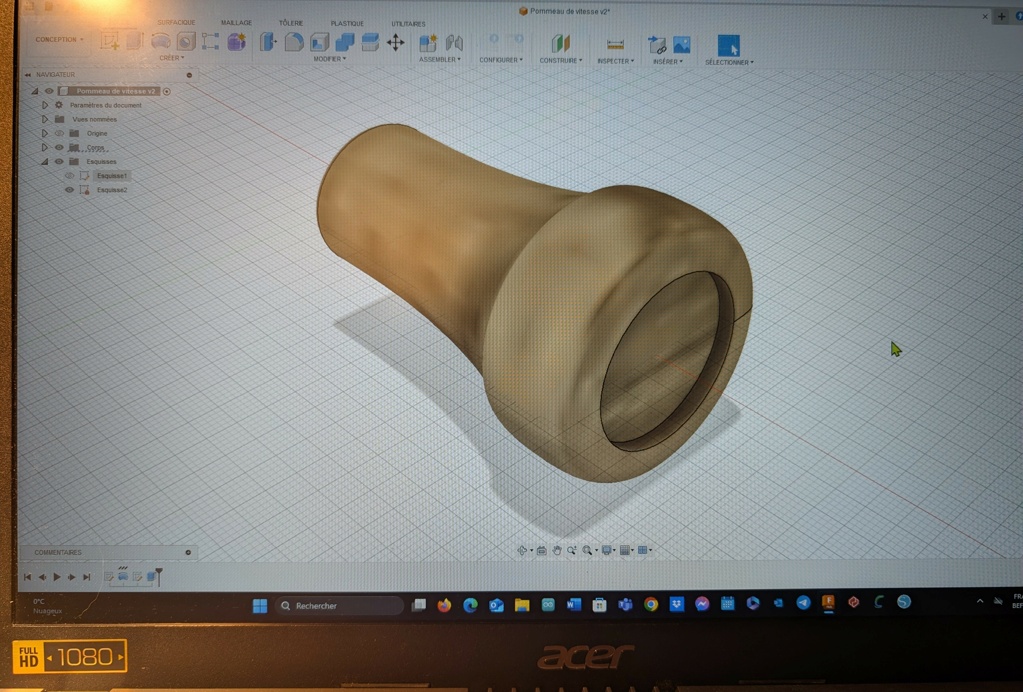

I have been working with Solidworks for several years and I am starting to use Fusion360.

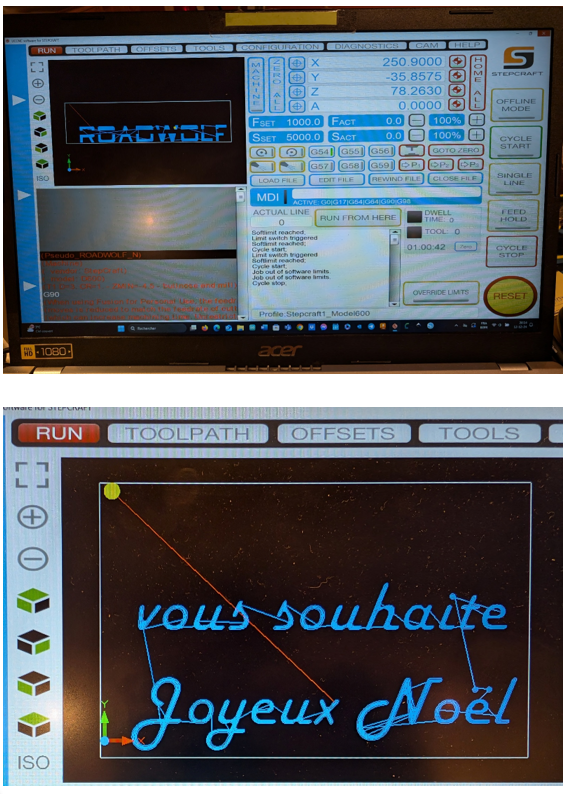

I bought StepCraft D600 from 2018, I tested it, it works well.

I calibrated the X-Y-Z axes. I managed to mill a drawing on X-Y.

I bought MM1000 and HF500, motors.

I bought a tool changer.

I bought a 4th axis.

I would like to do several different projects in brass, wood and plastic.

Now, I would like to try my 4th axis material to make a BMW gear knob, to practice, it is very complicated to set up in Fusion 360, how do you do it please?

Regards,

Vincent

STEPCRAFT D.640 (2018) - UC100

Softwares : UCCNC v.3.6 // Fusion 360 (3D + G-code) // Solidworks // Inskape 2D .

Options : Tool Lenght TS-32 // 4th axis // MM1000 // HF 500 // Tool Change // to be continued...

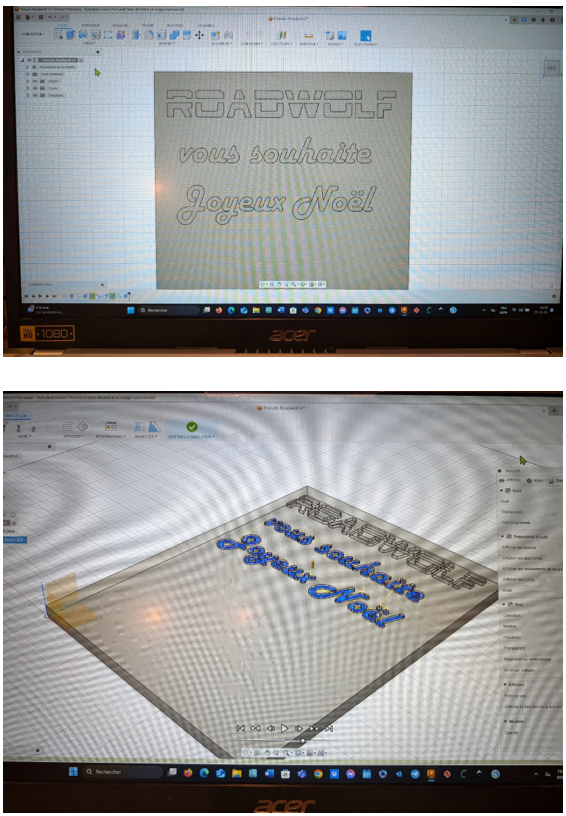

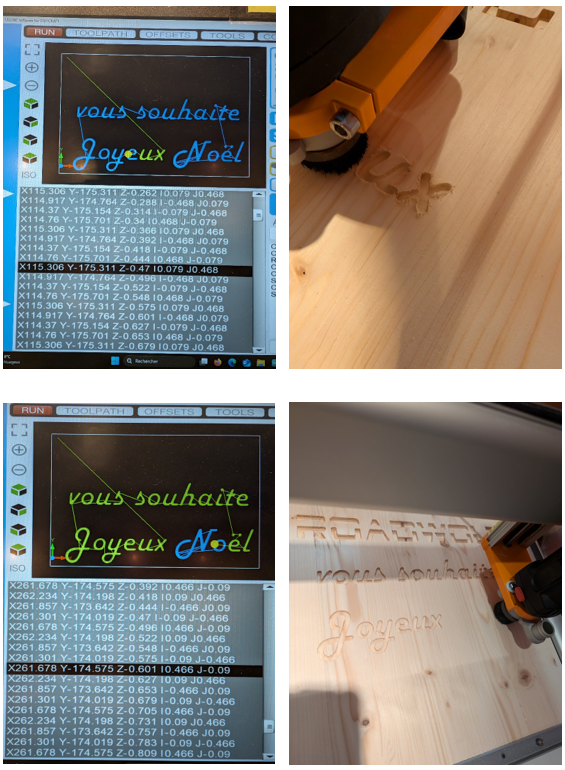

Deuxième test avec mon Stepcraft D600 :

[url=https ://servimg.com/view/16993513/2632][img]  [/img][/url] [url=https ://servimg.com/view/16993513/2633][img]

[/img][/url] [url=https ://servimg.com/view/16993513/2633][img]  [/img][/url] [url=https ://servimg.com/view/16993513/2634][img]

[/img][/url] [url=https ://servimg.com/view/16993513/2634][img]  [/img][/url] [url=https ://servimg.com/view/16993513/2635][img]

[/img][/url] [url=https ://servimg.com/view/16993513/2635][img]  [/img][/url]

[/img][/url]

STEPCRAFT D.640 (2018) - UC100

Softwares : UCCNC v.3.6 // Fusion 360 (3D + G-code) // Solidworks // Inskape 2D .

Options : Tool Lenght TS-32 // 4th axis // MM1000 // HF 500 // Tool Change // to be continued...

Just for fun

[url= https://i41.servimg.com/u/f41/16/99/35/13/conten10.pn g" target="_blank">https://i41.servimg.com/u/f41/16/99/35/13/conten10.pn g"/> [/img][/url]

https://servimg.com/view/16993513/2643

STEPCRAFT D.640 (2018) - UC100

Softwares : UCCNC v.3.6 // Fusion 360 (3D + G-code) // Solidworks // Inskape 2D .

Options : Tool Lenght TS-32 // 4th axis // MM1000 // HF 500 // Tool Change // to be continued...

Just for fun, my construction

STEPCRAFT D.640 (2018) - UC100

Softwares : UCCNC v.3.6 // Fusion 360 (3D + G-code) // Solidworks // Inskape 2D .

Options : Tool Lenght TS-32 // 4th axis // MM1000 // HF 500 // Tool Change // to be continued...

Here is my knob for my 4th axis, next experience in Fusion360,

I discover 😀 🤓 alone

[url= https://i41.servimg.com/u/f41/16/99/35/13/pxl_2070.jp g" target="_blank">https://i41.servimg.com/u/f41/16/99/35/13/pxl_2070.jp g"/> [/img][/url]

STEPCRAFT D.640 (2018) - UC100

Softwares : UCCNC v.3.6 // Fusion 360 (3D + G-code) // Solidworks // Inskape 2D .

Options : Tool Lenght TS-32 // 4th axis // MM1000 // HF 500 // Tool Change // to be continued...

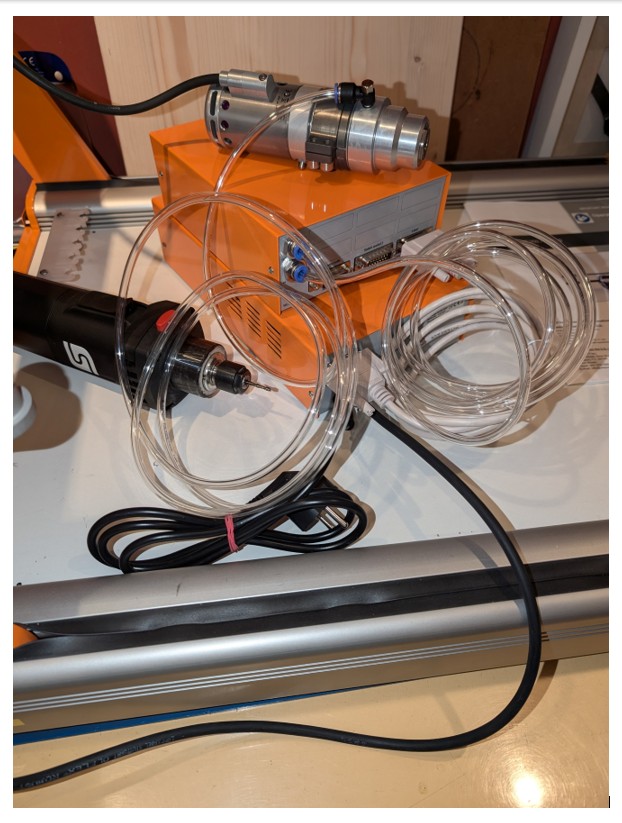

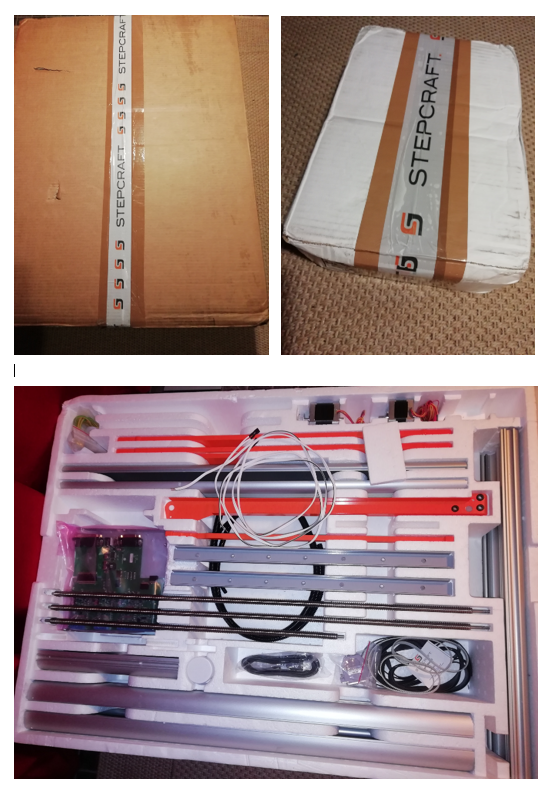

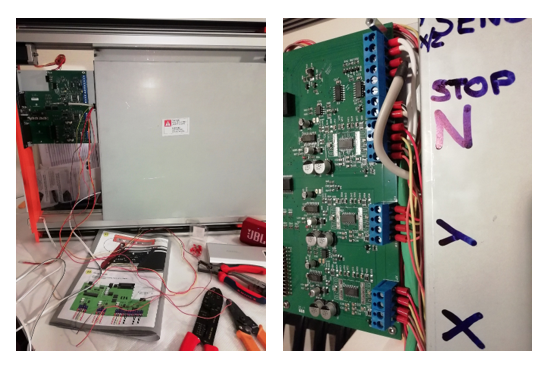

Well, these last two months, I bought some nice equipment from STEPCRAFT.

After assembling my Stepcraft D600 + adjusting + calibrating + studying and testing Fusion360 and UCCNC software a bit, then I can continue to buy STEPCRAFT equipment.

- A HF 500 W motor bought, I now have to study how the speed controller works with Fusion360 Autodesk software.

- A HF Spindle tool changer kit.

But I have to check the pneumatic system, because it seems to me that the pneumatic system is not correctly assembled in the orange Stepcraft housing. (photo to follow in a next dedicated technical blog if the problem continues). The pressure must be at 8 bars.

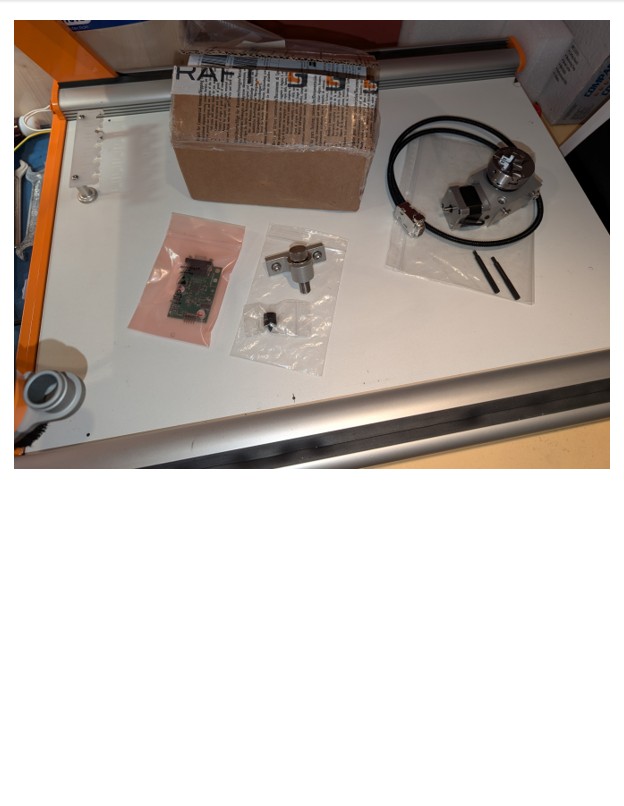

- A new 4th axis kit bought. I installed the electronic card. The "A-axis" motor (4th axis) runs well. Great: installed and tested.

Now, I have to connect with the parameters set in my design & manufacturing drawings on Fusion360.

- I bought ER11 collets and some SK15 tool holders for the automatic tool changer

- I bought a drill height sensor

I will continue with a new UCCNC software + a new aluminum plate + fixing parts and ... drill bits !

STEPCRAFT D.640 (2018) - UC100

Softwares : UCCNC v.3.6 // Fusion 360 (3D + G-code) // Solidworks // Inskape 2D .

Options : Tool Lenght TS-32 // 4th axis // MM1000 // HF 500 // Tool Change // to be continued...

view on : Kit Motor HF 500 W + Motor 1000 W + Kit change tools

STEPCRAFT D.640 (2018) - UC100

Softwares : UCCNC v.3.6 // Fusion 360 (3D + G-code) // Solidworks // Inskape 2D .

Options : Tool Lenght TS-32 // 4th axis // MM1000 // HF 500 // Tool Change // to be continued...

Kit tools 4th axis

STEPCRAFT D.640 (2018) - UC100

Softwares : UCCNC v.3.6 // Fusion 360 (3D + G-code) // Solidworks // Inskape 2D .

Options : Tool Lenght TS-32 // 4th axis // MM1000 // HF 500 // Tool Change // to be continued...

This wednesday, 8 january, I received my order from Stepcraft in Brussels. Quick, ordered friday evening.

1 Sensor : Buy Tool Length Sensor TS-32 for CNC Routers | STEPCRAFT

2 SK15 : Tool Holder for ATC KRESS AMB

1 box ER11 : Buy Collet Set ER11 | STEPCRAFT

There is a compatibility problem with my 2 new SK15 (for ER 11 collet tool): the tool changer I bought from someone seems to be compatible with SK10.

So next time I will buy a bigger tool changer for SK15 collet tool. If you had, call me.

It is not useless, because this small tool changer is rather intended for engraving, so it's good, to encourage me to do engravings too.

1) -> Automatic Tool Changer HF Spindle for CNC Routers | STEPCRAFT

2) -> Tool Changer for MM-1000, KRESS, AMB | STEPCRAFT

A+

Soon

STEPCRAFT D.640 (2018) - UC100

Softwares : UCCNC v.3.6 // Fusion 360 (3D + G-code) // Solidworks // Inskape 2D .

Options : Tool Lenght TS-32 // 4th axis // MM1000 // HF 500 // Tool Change // to be continued...

Saluer!

Bonjour Bruxelles  !

!

CE vendredi 17 janvier 2025, j’ai acheté le dernier logiciel UCCNC, la version 3.6. Je n’avais presque jamais utilisé la machine, en raison d’un excès de priorités et de projets. Ici c’est fait et je viens de l’installer :

CE vendredi 17 janvier 2025, j’ai acheté le dernier logiciel UCCNC, la version 3.6. Je n’avais presque jamais utilisé la machine, en raison d’un excès de priorités et de projets. Ici c’est fait et je viens de l’installer :

FRANCAIS : Ce vendredi j’ai acheté le dernier logiciel UCCNC, la version 3.6. Je ne m’étais presque jamais servi de la machine, à cause d’un excès de priorités et de projets. Voilà c’est fait :

FRANCAIS : Ce vendredi j’ai acheté le dernier logiciel UCCNC, la version 3.6. Je ne m’étais presque jamais servi de la machine, à cause d’un excès de priorités et de projets. Voilà c’est fait :

https://servimg.com/view/16993513/2650

https://servimg.com/view/16993513/2651

Sacrée évolution 😉

STEPCRAFT D.640 (2018) - UC100

Softwares : UCCNC v.3.6 // Fusion 360 (3D + G-code) // Solidworks // Inskape 2D .

Options : Tool Lenght TS-32 // 4th axis // MM1000 // HF 500 // Tool Change // to be continued...

- 44 Foren

- 7,436 Themen

- 63.4 K Beiträge

- 7 Online

- 26.5 K Mitglieder