Hello from Portugal!

I'm considering a S-2/600 plus a few bells and whistles, but in order to buy the correct soft and hardware combination there's a number of questions I'd like to ask. Perhaps the best thing would be to open a thread for the purpose, so I'd like to ask where in order not to disrupt the forum discipline.

The purpose is scale modelling with a commercial intent, and the design software is Rhino but we'll go into more details later.

Nice to meet you!

Clockwork Orange is a S600 with 4th axis, Kress 1050. Software is UCCNC, DeskProto, Rhino, DraftSight. Also a Silhouette Cameo for vinyl, plastic card, etc.

My package duly arrived last tuesday. After a day spent in contemplation there's the working table assembled; quotes for the enclosure sent out; ventilation, dust collection and exhaustion outdoors all figured out.

Now for the assembly proper. Shoot, Thankfully I'd bought a lot of parts storage boxes to sort all the plastic bags out! It's a damn lot more parts than I expected, that means I'm going to need a whole lot more duct tape!!!

😛

And three more cheers for Rory von StoneyCNC !!!

Clockwork Orange is a S600 with 4th axis, Kress 1050. Software is UCCNC, DeskProto, Rhino, DraftSight. Also a Silhouette Cameo for vinyl, plastic card, etc.

I would recommend you do a more or less full mechanical assembly before wiring the machine - it's so much easier to get the tuning correct without the encumbrance of the wiring hindering everything you do.

You will find the Y-axis in particular needs very careful "tuning" to get free movement over the full extent of the axis. In my machine I had to relieve the Y-axis leadscrew remote end bearing seats to avoid binding of the precision nuts.

Make sure the two gantry side arms are both set to the same angle - I temporarily fitted mine to the same side guide with the two vertical faces of the side arms together, parallel and at 90 degree to the guide rails - careful positioning of the fixed rollers will let you achieve this. Don't rush this step as it ensures the spindle will be close to correctly trammed.

Be careful not to over tighten the adjustable rollers during final assembly - it is too easy to jam the y-axis particularly, I tightened mine until free movement was just eliminated. In my view the recommendations in the Stepcraft manual puts too much load on the guide rails and could lead to mechanical damage at contact points.

Another point worth checking is that the "homing" micro-switches operate before mechanical limits are reached!!

On the software side, UCCNC is an excellent choice and, coupled with the UC100, frees the controlling PC/laptop from all critical timing issues.

Just my personal views - no connection to any H/W or S/W vendors.

Good luck - and don't rush things, patience will pay dividends in the end.

Peter

SC 420/2, Industrial VFD spindle from StoneyCNC

UC100 + UCCNC

Cut2D, Autosketch10, Draftsight, Eagle 9.5.1

There is no problem, however simple, that cannot be made more complicated by thinking about it.

Thank you Peter, your advice sounds entirely reasonable and I shall take it in due consideration. I find the supplied assembly instructions well thought out so with all this I have no doubt I'll be able to do a good job of it in a reasonable time 🙂

Clockwork Orange is a S600 with 4th axis, Kress 1050. Software is UCCNC, DeskProto, Rhino, DraftSight. Also a Silhouette Cameo for vinyl, plastic card, etc.

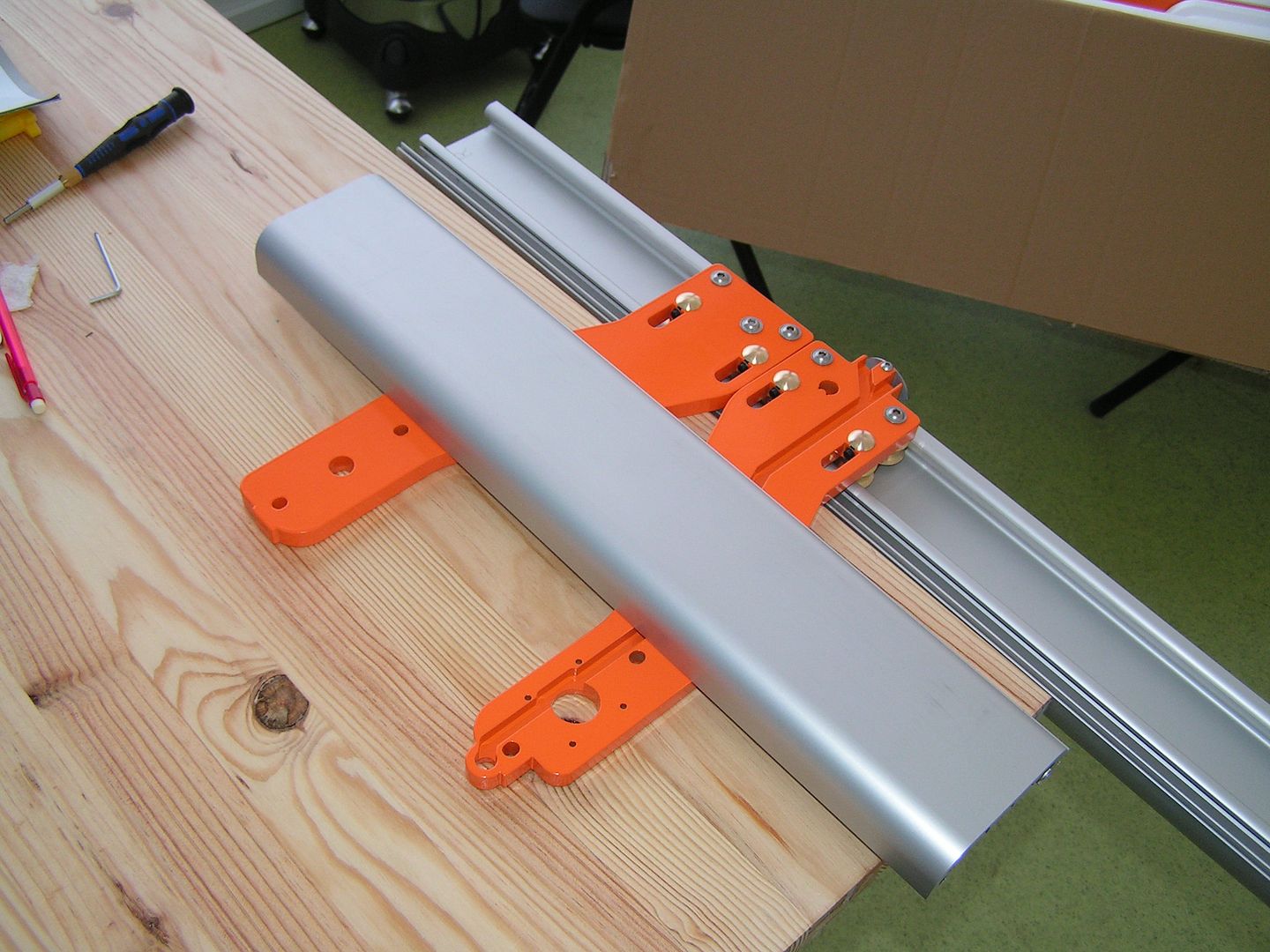

As you see I am assembling the gantry uprights. I am running them temporarily in the same rail to see how they line up. I have tried to adjust the rollers by loosening and re-tightening, but the two uprights do not land perfectly flat, there is a small difference of 2mm level at the top end of the uprights, that is, close to that big woodknot.

Is this 2mm difference a problem? If it isn't, fine.

If it is, the only solution that comes to my mind is to dismantle the bottom rollers, ensure the washers are all turned to the same side (they may be slightly concave), check that the rollers themselves have all the bearings well seated (rubber mallet) and tightening up again and see what comes out.

The table is level and smooth 🙂

Any advice?

Clockwork Orange is a S600 with 4th axis, Kress 1050. Software is UCCNC, DeskProto, Rhino, DraftSight. Also a Silhouette Cameo for vinyl, plastic card, etc.

If you swap positions on the rail, then the two long straight edges where the X-axis fits are the ones I suggested you check for parallelism and 90degrees. They would be close together, making this adjustment much easier.

I suspect that the 2mm you mention will not cause a problem - I don't remember whether I had a difference on my machine when I checked. The error will sort itself out when the X-axis is fitted and tightened, after which the Y-axis rollers should be adjusted for no shake in the gantry.

The 2mm could well be due to a slight difference in powder coating thickness under the washers - it wouldn't need a lot to give the discrepancy you see. Check with a straight edge, the electrostatic field used when the powder is applied tends to build a ridge close to any corner or hole.

If I remember correctly, the washers are very slightly dished, and if mounted with the concave surface towards the bearing on at least one roller the washer actually touched the bearing shield, making the roller very difficult to turn. This is not a good idea!!

Peter

SC 420/2, Industrial VFD spindle from StoneyCNC

UC100 + UCCNC

Cut2D, Autosketch10, Draftsight, Eagle 9.5.1

There is no problem, however simple, that cannot be made more complicated by thinking about it.

Thank you again, Peter, your help is being quite precious 🙂

The assembly is going on well, no snags due to the general quality and to the "Mechatronics for Dummies like Miguel (that's me!)" style manual. It's not foolproof but then you have to be a special kind of a fool to overproof that 😆

I have another comment to make. I did run on a snag as in the kit that I'd ordered from StoneyCNC there was a problem with a particular brass screw nut, something that was not really critical as that particular point in the sequence could be bypassed for a while. I sent word to them Monday morning, and the courier was on my doorstep with the part on Tuesday mid-afternoon! If this isn't reputation then I don't know what it is!

Cheers!

Miguel

Clockwork Orange is a S600 with 4th axis, Kress 1050. Software is UCCNC, DeskProto, Rhino, DraftSight. Also a Silhouette Cameo for vinyl, plastic card, etc.

Hi Miguel,

Glad the assembly is proceeding well - yet again Rory has exemplified true customer service.

Keep up the good work.

Peter

SC 420/2, Industrial VFD spindle from StoneyCNC

UC100 + UCCNC

Cut2D, Autosketch10, Draftsight, Eagle 9.5.1

There is no problem, however simple, that cannot be made more complicated by thinking about it.

It took some time, but today I had the immense pleasure of having my first test object designed by me milled out fulfilling the full cycle CAD / Cut2D / UCCNC / Stepcraft !

Nothing important, just some irregular shape with some holes in it, but it went on from start to end without a hitch.

As a matter of fact the Clockwork Orange had finished assembly and run UCCNC dry tests a week ago, since then time was spent on a DIY sound and dust enclosure - to tell you the truth the industrial grade vacuum cleaner drowns out the rest, so I came to question the wisdom - and then importing my DXF files into Cut2D. To tell you the truth the impediment was my sleep apnoea, I must have dozed off at a critical point in the appropriate Vectric Cut2D tutorial and I only caught that particular point today watching the same tutorial! That was the Fiat Lux moment!

I have to add that during assembly there were a few hiccups like the one I mentioned before, finally diagnosed as having to do with the interface card between the control board and the UNC100. It took a bit of emails back and forward to trace the defect, and I have no compunction in stating that Rory Stoney was completely professional and competent, and also helpful and humorous when I occasionally blew my lid! Per my experience with some vendors I would have ended up with an expensive disaster, definitely not so with Rory.

So now it will be a matter of fooling around with a few projects requiring 2D parts only. In due time I'll move on to 3D and the 4th axis. At the time I'll know whom to talk to 🙂

Clockwork Orange is a S600 with 4th axis, Kress 1050. Software is UCCNC, DeskProto, Rhino, DraftSight. Also a Silhouette Cameo for vinyl, plastic card, etc.

- 44 Foren

- 7,436 Themen

- 63.4 K Beiträge

- 5 Online

- 26.5 K Mitglieder