tool length sensor

hi all

how do you hook up the stepcraft tool length sensor ,

I'm using uccnc,

Will have answer for this soon.

You have to configure the probe feature.

do you have sensor?

Thanks rory

yes already have the sensor

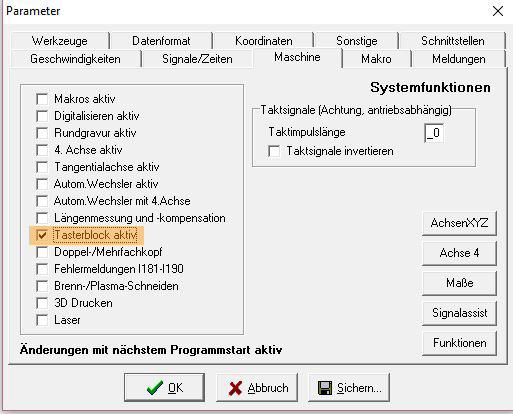

-)Hi how are you.ı get 840 but I tried every think and also checked toollenght sensor selfcheck but it doesnt work for me.Maybe its about winpc-nc usb full version doesnt support tool lenght sensor.what must ı do ?what am I doing wrong?I checked cable places also reverse cables with connection of sensor and also inverted 15inv in parameters also in signals it shows red but eventought I press lenght sensor it doesnt change the red color.

2-)ı checked 3 times the cables wirings but some times I get ofset error in milling and 3d printing.when I begun to machining it beguns good and doing the machining but at the middle of work it retarack and continues from another point of stock.

I m just learning not a professional.ı m using and foam for not to damage the cnc.Thanks best regards.I m using aspire and fusion 360 gcode in mach mm arcs postproccesor.

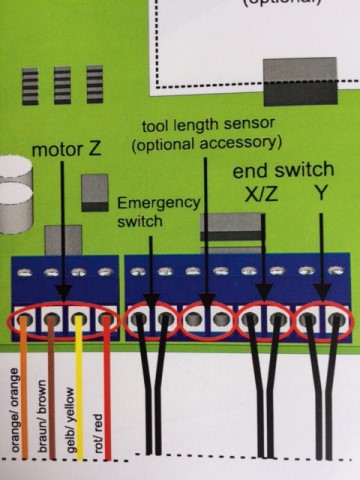

Hi, normally the tool length sensor is connected to Pin 10 and not 15.

WinPcNc does support the tool length sensor, but as I am using UCCNC therefore I can't tell you how to set it up.

Regarding your problems with the offsets during milling: Did you ground your machine? This sounds pretty much like the grounding problem.

MfG

Roy

SC 600/2; SolidWorks; UCCnC und UC100; EstlCam und Arduino Steuerung; KRESS 800kfme;

Bubbat,

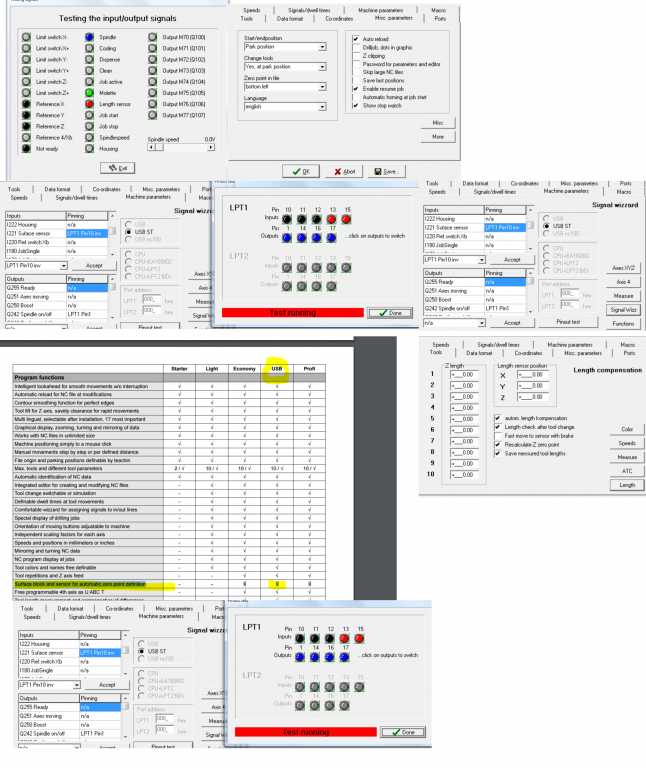

Hooking up your tool lenght sensor in WinPC-NC USB step by step.

First things first connect the two wires on the mainboard of the Stepcraft.

In WinPC in "parameters" at tab Special your settings are correct;

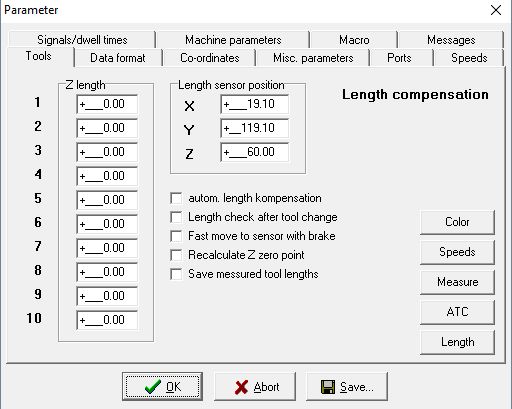

- now select tab Tools uncheck all choices, unless....

you have your toollenght sensor placed at a fixed position on the working area, if so..

select the designated X,Y position and the starting Z height;

then check the desired options in the check boxes.

Normaly you would not use this but place the sesor at your workpiece and measure the Z-height and calculate the null position.

So next you place your material,

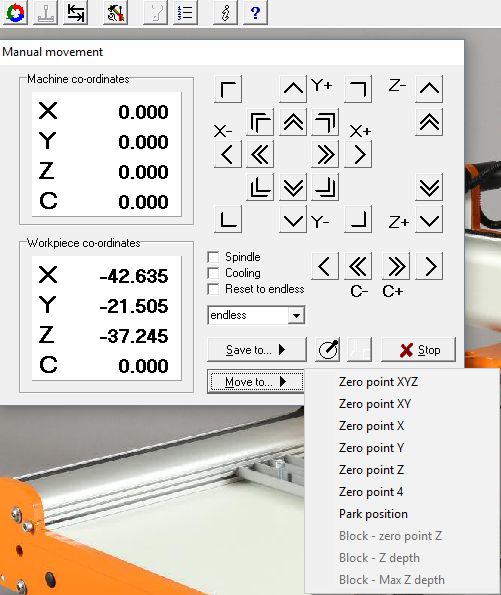

1- set your X an Y-axis start (null) position,

2- place your sensor on a wanted place on your workpiece,

3- use the manual movement tab and move your millbit over the sensor,

5- select "move to" and click on "Block - zero point Z", now the Z-axis will slowly move downwards until the switch is activated.

5- exit the manual movement tab, remove the sensor and hit F3 to start your first cutting, if you need a toolchange during your project the program will after the first job move to the park position and ask for the toolchange. Change your tool and click on the little manual movent pictogram on the bottom right and repeat step 3, 4 and 5.

The standard correction of the stepcraft toolsensor height is +32.50 mm this you can find at "parameters" tab Coordinates at the bottom left "surface block" , you can adjust this if needed.

this should work, so good luck

SC 1/420 + Gantry extension, Kress 1050 FME-P, NeJe 20W Laser, WinPC-NC USB v4.00, Vectric Aspire 9, SolidWorks 2021

thanks brothers,I did all you sad but when I pressed to "Block - zero point Z" ,z axis goes upwards fast and stops ,no slowly move downwards until the switch is activated.I tested sensor out of cnc machine as a switch,and no problem with sensor and cables,I m on to freak how to use this,I mailed to stepcraft 4 times but no answer,I dont know what must I do?

Hi,

I've set up my tool length sensor according to all of the instructions but it seems I've got something wrong or its buggy. Its set up with the M31 macro in the correct folder,UCCNC pin set to 10, and the input next to it set to 1.

Here's the deal: when I have the second input set to 1, the program says the switch is already active (which it is not). When I press the switch, the program starts lowering the Z axis like its supposed to - so it seems that the switch position must be somehow backward.

So I set it to 0 and the Z lowers as normal, but doesn't stop when it hits the switch, just keeps lowering.

Unsure what Im doing wrong here and don't want to make a costly mistake?

hi,I watched videos about win pc nc parameters and try what you say also support tteam mailed me some videos,but still not working for my cnc.I recorded a video that shows all my parameters and tool lenght sensor and the other thinghs,I think very interesting problem I have.How can we solve this problem.any help will b great ,best regards here is the link that the video.(it was big so I paste you the download link).thanks.

For UCCNC and Joshua: scroll up to Uli_D post and download the M31 macro. Maybe this one will work:

M31

Viele Grüße

Hartmut

V2/420 China 800W wassergekühlt

UCCNC & ARDUINO ESTLCAM Controller

ESTLCAM & QCAD

-----------------------------------

DK5LH/G11

Bubbatt,

Idiot idea but have you checked your switch with a multimeter if its working?

When I see you video there is no reaction by the switch.

SC 1/420 + Gantry extension, Kress 1050 FME-P, NeJe 20W Laser, WinPC-NC USB v4.00, Vectric Aspire 9, SolidWorks 2021

No bro ,not an idiot idea,you are right it must be check ,yes I checked sensor with a battery and a lamp and its working,also ı checked the motherboard of cnc,there is no damaged or imperfected thing,I connected the sensors wire to at the back side of motherboard pıns of sensors wire socket,but still nothing.any help will be great

- 44 Foren

- 7,435 Themen

- 63.4 K Beiträge

- 9 Online

- 26.5 K Mitglieder