Industrial Quality Small HF Spindle from StoneyCNC

Some of you may have already seen the YouTube videos I produced recently showcasing StoneyCNC's new industrial quality small HF spindle:

http://stoneycnc.com/en/stepcraft-/applications/milling/490

"Industrial quality HF spindle system that will run on an LPT connector to control the on/off and spindle speed functionality. This spindle can be controlled with the STEPCRAFT machine directly if the correct adapter cable is also purchased. This spindle is self cooling, fully balanced and has double angle contact bearings of very high quality. This is an industrial grade three phase motor system The spindle is driven by industrial Variable frequency drive (VFD). The VFD has overcurrent, over temperature and other important safety features to help protect your motor of the course of its life." StoneyCNC have been using VFD's in their commercial machines for years.

on this thread:

http://www.stepcraft-systems.com/en/forum/accessories/4052-hf350-making-unpleasant-noises

If not, I append the links to the videos to this thread. The toolpaths were around 1h 45m for each section of the replica Brian May Red Special guitar that I am making using my Stepcraft 2/840 machine. This demonstrates how well the Stepcraft machine copes with relatively long toolpaths. Whether the industrial HF spindle has some part in making life easier for the CNC machine is not known. Rory hasn't divulged the specification of the spindle to me yet but has only stated that I will be surprised at the specification. 😉 What this does demonstrate is that the "Steppi" will operate happily without losing steps for hours if it is properly set up.

The control unit is made by Delta of Taiwan. The user manual (8.27 MB) can be found here which is very comprehensive.

Next up for me is a cut of a foldable net from 1.2 mm thick aluminium sheet. If I can get the "AcL" (Abnormal Communications Loop) fault code to reset, I hope to run and video this toolpath today.

Regards.

Doug

http://www.youtube.com/watch?v=gGzD4v3TRUI

http://www.youtube.com/watch?v=mlzdxmOpnp8

http://www.youtube.com/watch?v=3-wKPZwJSMw

Stepcraft 2/840, StoneyCNC industrial HF spindle, 4th axis, TurboCAD 2016 Professional 64 bit, MeshCAM, GWizard feeds & speeds calculator, UCCNC

Hobby use: guitar building (luthiery), https://dsgb.net

To 'cut' a long story short. I attempted another cut on a piece of blockboard which was made with care to the correct dimensions using quality Spruce tonewood bracing strips.

It seems that my 4 mm four flute solid carbide flat end mill was blunted and heat damaged because it ploughed in after not very long.

Rory advises that I should be using two flute end mills on timber, so that's what it will be in future. Shame I have spent so much on four flute ones! 😆 Just a warning to those that didn't already know this. There is no damage done - the workpiece/stock was quality timber but slightly warped and might not have yielded a usable guitar body section anyway.

The strip shows the results of test cuts with a 6.00 mm four flute solid carbide ball nose end mill. Burning burning burning even at 1.00 mm depth of cut. Yep, ball nose mills are for finishing only. This unfortunately means that my neck cut which is a double sided job will likely need four tool changes. I kind of wish that I had bought that automatic tool changer now.

I didn't have a good day yesterday. 🙁

Doug

Stepcraft 2/840, StoneyCNC industrial HF spindle, 4th axis, TurboCAD 2016 Professional 64 bit, MeshCAM, GWizard feeds & speeds calculator, UCCNC

Hobby use: guitar building (luthiery), https://dsgb.net

So, I successfully cut a pickguard set today. See attached images. Video to follow when edited and uploaded to YouTube.

I was highly embarrassed but very relieved to find that I was running both the 2 mm 2 flute cutter and the Trend 90 degree V groove cutter in the WRONG DIRECTION during last night's attempts!

This begs the question how on earth I managed to cut the aluminium switch plate at all! It does explain why it remained sharp though. Perhaps I should try again with the harder sheet I bought...?

92% successful job because the bit dug inward at the toolpath start/finish point.

Material: 3.0 mm (nominal) cast gloss black acrylic (Perspex)

Spindle speed: 7,500 rpm

XY feed rate: 1,000 mm/min

Z feed rate: 30 mm/min

Depth per pass: 0.5 mm

Doug

Stepcraft 2/840, StoneyCNC industrial HF spindle, 4th axis, TurboCAD 2016 Professional 64 bit, MeshCAM, GWizard feeds & speeds calculator, UCCNC

Hobby use: guitar building (luthiery), https://dsgb.net

What's with this forum - you can't edit your posts indefinitely?

Oh well, another post then just to add the video I couldn't add to my previous post and another image.

https://www.youtube.com/watch?v=LK4Av9CX-kQ

Stepcraft 2/840, StoneyCNC industrial HF spindle, 4th axis, TurboCAD 2016 Professional 64 bit, MeshCAM, GWizard feeds & speeds calculator, UCCNC

Hobby use: guitar building (luthiery), https://dsgb.net

Here is a 13 minute video of a successful cut of the aluminium switch plate for my Brian May Red Special replica guitar. Note that the screw hole drilling (2 passes only) is shown speeded up 8 x. I finished the drilling off later (not shown)

https://www.youtube.com/watch?v=vvjBx_inh0U

http://www.youtube.com/watch?v=vvjBx_inh0U

Material: 1.2 mm thick 5251 H22 grade aluminium sheet.

Spindle: industrial HF spindle from StoneyCNC.

Feed rate: 1,000 mm/min

Plunge rate: 30 mm/min

Spindle speed: 7,500 rpm.

2 mm 2 flute solid carbide slot drill (REVERSE ROTATION).

12 passes at 0.1 mm depth per pass.

As you can see the aluminium granulates nicely and generates small mobile chips which clear easily with these conservative parameters. I suspect the Stepcraft system would cut quicker and with slightly greater depth per pass but I have no requirement to push the boundary on the small geometries associated with this project. I did not apply any compressed air cooling as you can see and there was little or no heat build up in either the stock or bit. That said, I did pause between the six pocket cuts to remove gum from the double sided adhesive tape and swarf from the end of the cutter with a cloth and isopropyl alcohol.

Regards.

Doug

Stepcraft 2/840, StoneyCNC industrial HF spindle, 4th axis, TurboCAD 2016 Professional 64 bit, MeshCAM, GWizard feeds & speeds calculator, UCCNC

Hobby use: guitar building (luthiery), https://dsgb.net

This is another aluminium cut with exactly the same parameters as the previous post. This is a small potentiometer and capacitor plate today. Here is a short (normal speed) close up YouTube video of the cut:

http://www.youtube.com/watch?v=6P87CX_yd7w

Doug

Stepcraft 2/840, StoneyCNC industrial HF spindle, 4th axis, TurboCAD 2016 Professional 64 bit, MeshCAM, GWizard feeds & speeds calculator, UCCNC

Hobby use: guitar building (luthiery), https://dsgb.net

Today I had a go at making a perspex/acrylic template to align a CUT and radiused fretboard to a StewMac style dual scale fret slotting template:

Unfortunately, on the last 0.5 mm pass, I found that the eBay supplier had sent 3 mm acrylic sheet, not 4 mm as I ordered! You will see the larger section come away as the outline is cut. I also didn't put enough tape under it.

On a positive note, the single flute plastic cutter bit performed very well and left a very smooth opaque edge. I will use this for all acrylic cutting in future.

The movie is speeded up x4 to alleviate some boredom or appease the impatient.

http://www.youtube.com/watch?v=ayizlGIelog

Spindle speed: 7,500 rpm

XY feed rate: 1,500 mm/min

Z plunge rate: 30 mm/min

Depth per pass: 0.5 mm

Cutter: 2 mm single flute solid carbide plastic cutting bit

Material: 3 mm clear cast acrylic sheet

Stepcraft 2/840, StoneyCNC industrial HF spindle, 4th axis, TurboCAD 2016 Professional 64 bit, MeshCAM, GWizard feeds & speeds calculator, UCCNC

Hobby use: guitar building (luthiery), https://dsgb.net

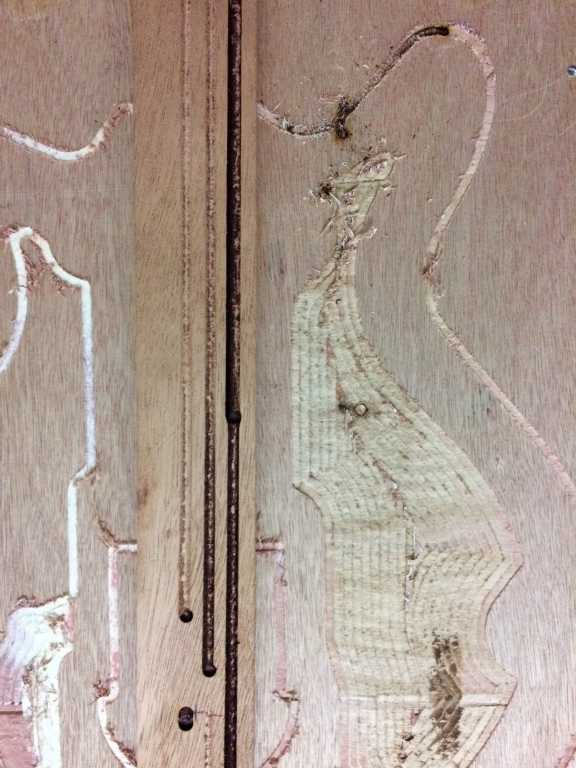

Here are some media from today's attempted neck cut. The upper side cut went just fine as did the lower side... right up until my wife came back and turned the microwave oven on to cook the evening meal! Unfortunately, turning large current consumers on or off on the same electrical ring main causes random issues for the CNC the machine. On the top side cut, about 20 minutes into the toolpath, the software crashed. This situation is recoverable if the machine (absolute) co-ordinates corresponding to the original zero point are jotted down. Just re-start the computer, home the machine, jog back to the original machine co-ordinates and re-zero the relative co-ordinates and start again.

However, in the second case, the current surge simply caused the next Z vertical increment to increase from 1.2 mm to what looked like 10 mm! The piece was ruined about 60 minutes into the roughing operation that might have taken about 90 minutes. I had no clue what had caused this until my wife overheard the expletives and came into the garage looking sheepish... 😆 Gotta laugh eh?

Anyway, here is the 10x speeded up YouTube video (9 minutes long):

http://www.youtube.com/watch?v=1GlAxiVl2Mc

Spindle speed: 20,000 rpm

XY feed rate: 2,000 mm/min

Z plunge rate: 120 mm/min

Depth per pass: 2.0 mm (roughing)

Stepover/stepdown: 1.2 mm (finishing)

Cutter: 5 mm two flute solid carbide slot drills (flat end for roughing, ball nose for finishing)

Material: Khaya (African Mahogany) tonewood neck blank (84.5 x 800 x 40.6 mm)

Spindle: StoneyCNC small industrial quality spindle

I have a number of learning points to address before I attempt another cut with the second Khaya neck blank. Probably the most significant being that I need to make a DIY dust boot/skirt. The one supplied with the Stepcraft machine has brushes which are too short for my applications and blocks access to the spindle shaft so to change cutting bits would require the spindle to be removed from its collar. I also need to put on a new MDF spoil board and add much more double sided adhesive tape because it was lifting at the ends. Not something I had noticed previously. Another oddity is that the truss rod channel was not routed to the correct depth. The roughing operation avoided it and the finishing toolpath had a go then went on strike. 😕

As it happens, this was a test cut on the first neck blank that got ruined back in October 2016 with my lack of knowledge and experience. The piece was re-usable but the heel that joins with the body would have been the only section of the neck with noticeable damage. With hindsight, I'm very glad I re-used this stock!

I have over an hour's worth of video footage of the roughing toolpath on the lower side. I might or might not edit and upload this. It doesn't show very much of interest for about 45 minutes after it has milled away the aborted previous cut then you can start to see the progress of the roughing operation.

That's my sixteen days vacation over and I'm back to work with a vengeance, so unless I can solve some of the issues before Thursday, that will be all from me for some weeks. 😐

Doug

Stepcraft 2/840, StoneyCNC industrial HF spindle, 4th axis, TurboCAD 2016 Professional 64 bit, MeshCAM, GWizard feeds & speeds calculator, UCCNC

Hobby use: guitar building (luthiery), https://dsgb.net

Milling a custom dust skirt plate from 12 mm thick acrylic sheet. The plate will have a 38 mm acrylic tube glued in to attach the vacuum extraction unit to and will have 75 mm brushes attached to each side with M4 machine screws into M4 brass press-in threaded inserts for plastic. NOTE: the video is speeded up 8x. Total cutting time was 18 minutes.

Parameters:

Material: 12 mm thick acrylic/Perspex sheet.

Spindle: industrial quality small HF spindle from StoneyCNC.

XY feed rate: 1,500 mm/min

Z plunge rate: 30 mm/min

Spindle speed: 7,500 rpm.

Cutter: 4 mm diameter 2 flute solid carbide slot drill.

24 passes at 0.5 mm depth per pass.

http://www.youtube.com/watch?v=T0iGVesYtxw

https://www.youtube.com/watch?v=T0iGVesYtxw

Video is speeded up 8x.

Doug

Stepcraft 2/840, StoneyCNC industrial HF spindle, 4th axis, TurboCAD 2016 Professional 64 bit, MeshCAM, GWizard feeds & speeds calculator, UCCNC

Hobby use: guitar building (luthiery), https://dsgb.net

Here's the latest effort: milling a fretboard for my Brian May Red Special replica guitar from an ebony fretboard blank. Note the video is speeded up 8x. The intention was to use a 6 mm ball nose end mill for the finishing paths but the GCode for the roughing toolpath included the finishing toolpath code too due to my error when saving it, so the entire run is done using a 6 mm flat end mill. The first path is just to thickness the 7.7 mm ebony stock to 7.0 mm.

https://www.youtube.com/watch?v=2FjiYE5iprU&feature=youtu.be

http://www.youtube.com/watch?v=2FjiYE5iprU

This looked good but for my second attempt I will leave out the 1/4" marker dot holes from the tool paths and drill these separately at the end with a 1/4" flat end mill.

I calibrated my tool height sensor and used this to zero from the spoil board + double sided adhesive tape then re-zero at Z+7.00 mm before I ran the thicknessing toolpath. This is much more convenient than the method I was proposing to use which involved touching off a piece of ground flat stock/gauge plate of the desired thickness using a cigarette paper.

Parameters:

Material: 7.0 mm thick ebony fretboard blank after running the thicknessing path (7.7 mm originally).

Spindle: industrial quality small HF spindle from StoneyCNC.

XY feed rate: 2,500 mm/min roughing (2,000 mm/min finishing)

Z plunge rate: 120 mm/min

Spindle speed: 18,000 rpm.

Cutter: 6 mm diameter 2 flute solid carbide slot drill.

0.6 mm stepover and step-down on the finishing passes.

The roughing toolpath took about 4 minutes and the finishing toolpath about 34 minutes making a total cut time of 38 minutes.

Doug

Stepcraft 2/840, StoneyCNC industrial HF spindle, 4th axis, TurboCAD 2016 Professional 64 bit, MeshCAM, GWizard feeds & speeds calculator, UCCNC

Hobby use: guitar building (luthiery), https://dsgb.net

Here is a vastly speeded up (15 x) video of me cutting the lower side of my Brian May Red Special guitar neck, Apologies for the presence of my Hobbit like bare feet in the background! 😳

http://www.youtube.com/watch?v=8zFTG1Ra8Z8

Unfortunately, there was a SNAFU literally a few minutes before the end of the roughing toolpath when the loose side piece interfered with the cutter and caused it to lose steps and dig into the headstock! This was foreseeable and I did consider that this might happen but forgot to intervene and stabilise or remove it. I am preparing two further Khaya neck blanks which are wider and the cutter path will not run outside the width breaking up the sides as with these first two stocks.

I elected to continue with the finishing toolpath and I'm glad I did because it the end result was highly satisfactory. I did about 30-45 minutes of filing and sanding outside in the sun and was rather pleased with the neck at that stage. It certainly gives me confidence that the tool paths are valid and without any glitches caused by operator inexperience will run to completion and produce a fine looking neck. I was particularly pleased with the volute bump area. I will take some close up photos of it and upload these in due course.

The total cut time was about 2 1/2 hours but the video is condensed to less than 10 minutes.

Spindle speed: 18,000 rpm

XY feed rate: 2,500 mm/min

Z plunge rate: 120 mm/min

Depth per pass: 2.0 mm (roughing)

Stepover/stepdown: 1.2 mm (finishing)

Cutters: 6 mm two flute solid carbide slot drills (flat end for roughing, ball nose for finishing)

Material: Khaya Ivorensis (African Mahogany) tonewood neck blank (84.5 x 800 x 40.6 mm)

Spindle: StoneyCNC small industrial quality spindle

Doug

Stepcraft 2/840, StoneyCNC industrial HF spindle, 4th axis, TurboCAD 2016 Professional 64 bit, MeshCAM, GWizard feeds & speeds calculator, UCCNC

Hobby use: guitar building (luthiery), https://dsgb.net

Some pictures after a degree of finishing with 180 grit abrasive paper:

Stepcraft 2/840, StoneyCNC industrial HF spindle, 4th axis, TurboCAD 2016 Professional 64 bit, MeshCAM, GWizard feeds & speeds calculator, UCCNC

Hobby use: guitar building (luthiery), https://dsgb.net

Hi Doug,

Impressive work - you must be well pleased.

Question, did you get your carbide bits from Eternal ?

Your VFD spindle has done you proud - I'll be setting mine to serious work soon when I cut the frames for my wooden clock, several hours of machining there!! So far I've barely tested it when machining printed circuit boards, it's nice to know it will always start when commanded and doesn't get hot enough to raise a blister!!

Peter

SC 420/2, Industrial VFD spindle from StoneyCNC

UC100 + UCCNC

Cut2D, Autosketch10, Draftsight, Eagle 9.5.1

There is no problem, however simple, that cannot be made more complicated by thinking about it.

https://youtu.be/ClI-MewWelw

Cutting some Brian May Red Special guitar pickup surrounds from cast black perspex/acrylic sheet. First I run a toolpath to reduce the thickness of the nominally 3 mm thick perspex to 2 mm thick (speeded up x20) then I abrade the machining marks out of the thicknessed area with 600 grit paper (not shown) then I cut the individual pickup surrounds (each one speeded up x8).

I used a 6 mm diameter 2 flute solid carbide end mill for the thicknessing toolpath and a 2 mm diameter 2 flute solid carbide TiAlN coated end mill to cut each pickup surround.

CNC machine: Stepcraft 2/840 with StoneyCNC small industrial HF spindle. Spindle speed 7,500 rpm, vertical (Z axis) feed rate 30 mm/min, XY axis feed rates 1,200 mm/min. Waterline toolpath only with a stepdown of 0.2 mm to achieve a reasonably fine rounded over outer edge.

Note that Brian's original pieces were approximately 1/16" (1.6 mm) thick but I prefer a slightly chunkier look so made them 2 mm thick.

Stepcraft 2/840, StoneyCNC industrial HF spindle, 4th axis, TurboCAD 2016 Professional 64 bit, MeshCAM, GWizard feeds & speeds calculator, UCCNC

Hobby use: guitar building (luthiery), https://dsgb.net

https://youtu.be/v88iNPrC8pQ

Cutting a replica Jeanrenaud DPDT parallel slide switch wafer from 1P/13 tufnol sheet (1.2 mm thick) using a 0.8 mm (1/32") diameter solid carbide flat end mill. Spindle speed 7,500 rpm. XY feed rate 750 mm/min. Vertical (Z) feed rate 30 mm/min.

Stepcraft 2/840, StoneyCNC industrial HF spindle, 4th axis, TurboCAD 2016 Professional 64 bit, MeshCAM, GWizard feeds & speeds calculator, UCCNC

Hobby use: guitar building (luthiery), https://dsgb.net

- 44 Foren

- 7,424 Themen

- 63.4 K Beiträge

- 0 Online

- 26.5 K Mitglieder